eps insulation

EPS Insulation

The word Styrofoam™ is often used to describe expanded polystyrene (EPS) foam; however, ‘Styrofoam’ is actually a trademarked term for closed-cell extruded polystyrene foam made for thermal insulation and craft applications. … Expanded Polystyrene insulation is a lightweight, rigid, closed cell insulation.

What is Expanded Polystyrene (EPS) foam?

The word Styrofoam™ is often used to describe expanded polystyrene (EPS) foam; however, ‘Styrofoam’ is actually a trademarked term for closed-cell extruded polystyrene foam made for thermal insulation and craft applications. EPS foam is the correct term for any form of expanded polystyrene.

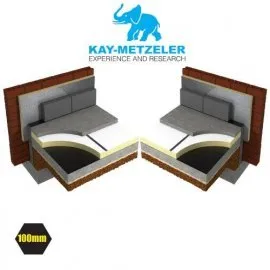

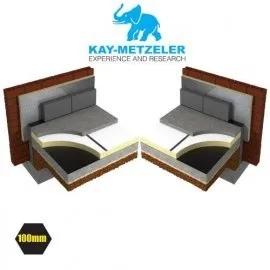

Expanded Polystyrene insulation is a lightweight, rigid, closed cell insulation. EPS is available in several compressive strengths to withstand load and back-fill forces. This closed-cell structure provides minimal water absorption and low vapor permanence.

Commonly used as insulation for walls, foundations and roofing, there are many benefits to selecting EPS products

:• Long-term R-Value (“R” is the resistance to heat flow)

• Energy efficiency

• Constant thermal resistance

• Measurable energy savings

• Strength• Sustainability

• No growth of bacteria, nor will it decay over time

• Dimensional stability

• Chemical inertness

• Low cost

A cost efficient, high performing alternative to extruded (XPS) foam, EPS is the perfect choice for many insulation and construction applications.

The Manufacturing Process

EPS is created in a two-stage process:

Raw beads are expanded using steam, creating pre puff beads, which are then cured in large bags before being conveyed to the mold. Once in the mold, the pre puff beads are again steamed to form a block that is anywhere from 37-1/2″ – 54″ x 49″ x 121-1/2″ – 220″. The blocks are then placed on the storage floor to age for the appropriate length of time before being cut into various shapes and sizes. Blocks are produced in several densities to meet specific project needs. Here at ICA we manufacture Low Density EPS foam blocks all the way up to 2.85 lb density.

EPS Size & Density

ICA’s new state-of-the-art Hirsch mold allows us to manufacture block sizes anywhere from 37-1/2″ – 54″ x 49″ x 121-1/2″ – 220″. Although ICA does not stock any cut foam, regularly cut sizes are: 48 inches by 96 inches and 24 inches by 96 inches. Almost any size is available as a custom order.

Thickness: 1/4″ to 54″

Lengths: Up to 216″ (18′)

Widths: Up to 48″

Densities: .75 lb to 2.85 lbs per cubic foot

Density is a measure of mass per volume. EPS is measured in pounds per cubic foot (lbs/pcf). ICA manufactures expanded polystyrene in the following minimum densities:

0.70 lbs/pcf

0.90 lbs/pcf

1.15 lbs/pcf

1.35 lbs/pcf

1.80 lbs/pcf

2.40 lbs/pcf

2.85 lbs/pcf